Technology > Imaging and Software

The TruDx2000 Imager is Akonni’s proprietary microarray imager, based on technology that was developed in-house. It consists of a high-intensity green light emitting diode (LED), custom optics, and CCD camera. The TruDx2000 Imager captures an image of the 3D gel drop array through a transparent window of an intact integrated microfluidic microarray consumable (IMMC), and includes automated analysis software that analyzes the image to determine the presence or absence of specific molecular targets. The Imager includes a barcode reader to link the sample ID number to the IMMC used for the test. When the barcode of the IMMC is scanned, test-specific data populates the test report, links the IMMC to the sample, and automatically sets test-specific imager parameters.

The Imager does not require user calibration, and the user does not have the capability to re-calibrate the instrument. All control parameters are protected and verified by an encryption algorithm with a master key. If the protected configuration is modified, the application will be prevented from running. Field service engineers from Akonni or an authorized distributor have access to a software calibration module. Field service engineers can use the calibration software to adjust the calibration setting and save the new settings using encryption. In addition, the instrument is calibrated at the factory against a master test object, and field checks can be performed by Akonni or a distributor with a reference array.

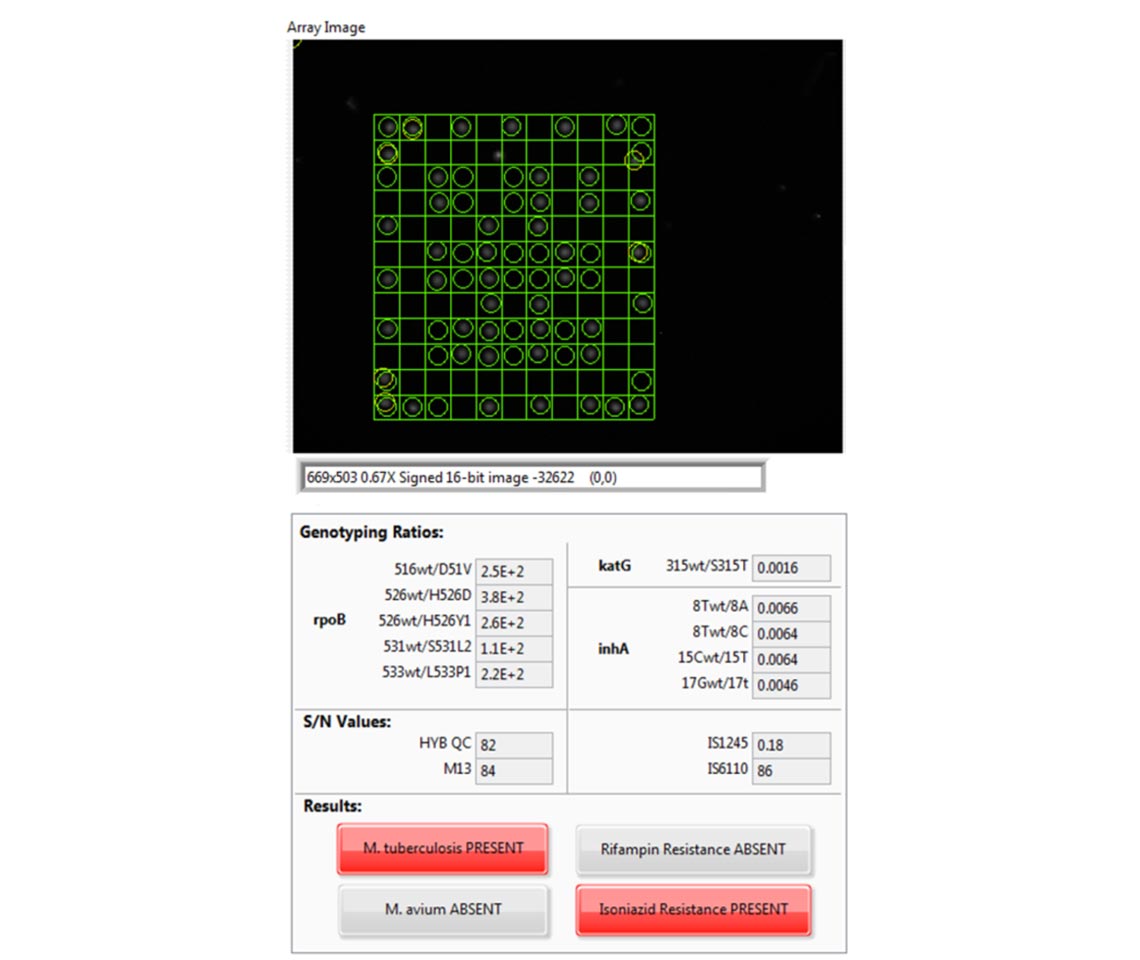

An example of a TruSpot software report

The TruDx2000 Imager includes several software modules which together allow users to process tests and seamlessly create reports of the testing results, which can be reported through integrated laboratory information management systems (LIMS) or independently. The primary software module is the application software, which allows user interaction with the instrument. All of the hardware functions of the instrument are controlled by embedded firmware under the command of the application software. A separate parameter file is used by the application software to create assay-specific results and reports – all of which is triggered automatically when the test cartridge is scanned. By keeping these assay-specific parameter files separate from the application, they may be individually validated.

The automated TruSpotTM software, integrated with the imager, locates and segments each individual microarray spot (automated grid placement) and reports signal-to-noise ratios (SNR). An algorithm is used to analyze and extract data from the image of the 3D gel drop arrays. Summary statistics and quality scores for every gel element on the array are automatically generated. The software is modular, and can incorporate new statistics, diagnostic calculations and plug-in modules on an as-needed basis, regardless of the microarray substrate.

© 2003-2025 Akonni Biosystems, Inc. All rights reserved. Terms and Conditions • Privacy Policy

TruDiagnosis Systems, TruDx Readers, TruArray Tests, TruTip Kits, Primers, Lysis and Binding Buffers, Wash Buffers and Elution Buffers: For Research Use Only. Not for use in diagnostic procedures. No claim or representation is intended to provide information for the diagnosis, prevention or treatment of a disease.